DWS Lab

Published as Lead Author in IEEE: “Integrated Centralized Framework for Industrial Automation,” showcasing a scalable approach to unify Modbus, EtherCAT, and DeviceNet protocols into an MQTT-based Industry 4.0 architecture.

Team Lead & Research Assistant & Lead Author

As Team Lead and Research Assistant in Purdue’s Design with Simulation (DWS) Lab, I led a project to integrate industrial protocols and IoT technologies into a unified framework. This work resulted in a peer-reviewed publication at an IEEE international conference, where I served as Lead Author.

Problem

Factory floors run heterogeneous protocols (e.g., Modbus, EtherCAT, DeviceNet) that don’t natively interoperate, creating data silos and blocking real-time visibility and Industry 4.0 adoption. We needed a scalable, interoperable way to translate these protocols into a unified, lightweight messaging layer without expensive proprietary gateways.

Methodology / Architecture

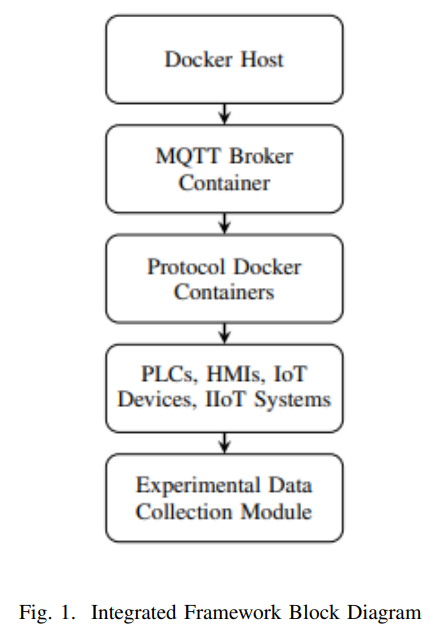

I designed a modular, containerized stack:

Protocol Translators (Docker containers): one container per protocol (Modbus TCP/IP, EtherCAT, DeviceNet) translating native frames to MQTT topics.

MQTT Broker: a centralized broker (Eclipse Mosquitto) enabling asynchronous, topic-based exchange across devices and applications.

Digital Twin Integration: bidirectional links to virtual replicas for monitoring/control and analytics.

Experimental Data Collection Module: subscribers that log MQTT topics for validation and analysis.

Implementation

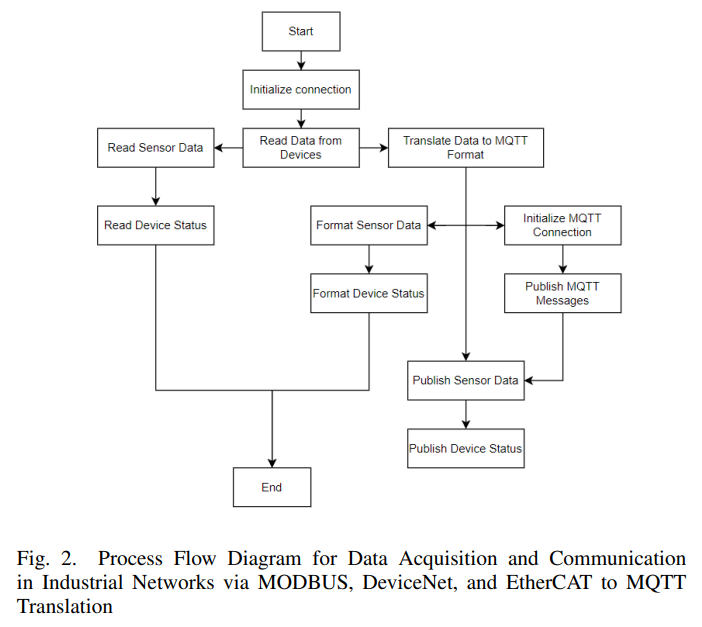

I built translator containers with Python to implement per-protocol logic and publish to MQTT:

Modbus TCP/IP: polling registers/coils → structured MQTT messages.

EtherCAT: cyclic monitoring of control/status words → MQTT.

DeviceNet: CAN frame listener → MQTT event publishing.

The Eclipse Mosquitto broker handled multi-device, asynchronous traffic. Topic subscriptions powered the experimental collection module and digital twin views

Technical Setup & Data Handling

I validated translation integrity by comparing raw Modbus data to the MQTT-translated output, then publishing to a test broker and subscribing with a separate client to confirm end-to-end consistency. Additional analysis included comparative review vs. direct protocol gateways and middleware, highlighting the deployment ease, scalability, and isolation benefits of containers (with acknowledged network/config overhead).

Validation & Analysis

The setup included industrial sensors/devices over Modbus TCP/IP, Python scripts in Docker for translation, and Eclipse Mosquitto as the broker. Logged MQTT streams were stored for further time-series analysis, anomaly detection, and optimization within the same Docker environment; the digital twin feedback loop allowed real-time adjustments based on analytics outputs.

Key challenges addressed in the paper include:

Inter-protocol differences (rules, message structures, timing) when mapping to MQTT’s lightweight model.

Real-time handling vs. MQTT’s asynchronous nature (ordering, latency considerations).

Security/authentication (TLS/SSL, robust auth) for sensitive industrial data.

Scalability & resource management when running many containers; robust error handling/diagnostics across translators.

Challenges & Limitations

The framework unified Modbus, EtherCAT, and DeviceNet under a single MQTT-based layer, enabling real-time data exchange, monitoring, and control, with containerization providing modularity, isolation, and scalable deployment. The paper positions this as a practical step toward Industry 4.0 through standards-aligned, software-defined interoperability